(503) 295-3000 | orders@4boxes.com

Subotnick is proud to be an authorized and factory trained distributor of Wulftec equipment. We offer their complete line of semi-automatic, automatic, turntable, and rotary arm wrappers.

Download Brochure See Featured Models

Are you still manually wrapping loads because you think a stretch wrapping machine is too costly for your current needs? Purchasing equipment which more efficiently uses stretch wrap film by stretching the film two to four times its original length before applying it will significantly reduce film usage. Based on film costs alone, a machine can be justified within two years for a facility currently hand wrapping as few as 10 loads a day.

With the combination of the right stretch wrap equipment and film, you will securely wrap your pallets and avoid potential damage from dirt, dust, or moisture.

Semi-Automatic and Automatic systems will stretch your film to its full potential. Stretch wrap is a petroleum-based product; Use less, spend less, and improve performance.

Improve worker safety by eliminating wear-and-tear injuries and fatigue caused by hand stretch wrapping. Equipment will minimize worker injury rates associated with hand wrapping.

By investing in a stretch wrapping system, you will save a lot of operator time and effort that you can then repurpose into other important needs.

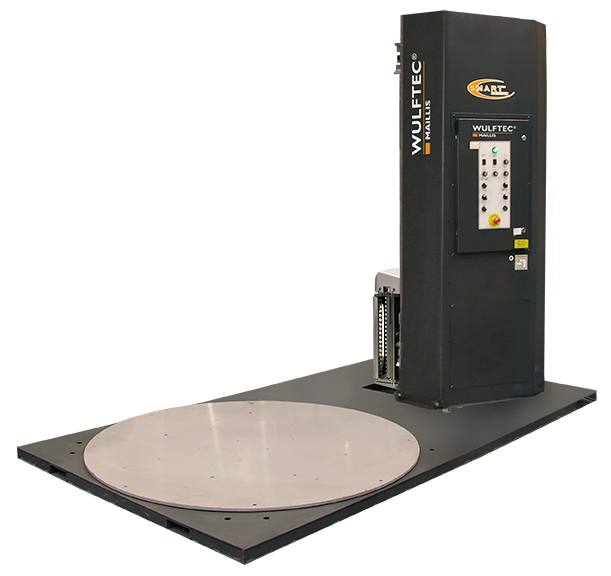

With a production rate of 55 loads per hour, and a 65″ diameter turntable with 5000 lbs. load capacity, this semi-automatic standard base, low-profile turntable stretch wrapping solution will meet a variety of application requirements. All Wulftec systems come standard with Allen Bradley controls, 20″ No-Thread lifetime warranty on pre-stretch rollers, and much more. Systems are customizable with a full complement of options to your needs and can include safety packages for your environment.

Download PDF

With a production rate of 100 loads per hour it will keep up with the most demanding production rates. A maximum load size of 48″ L x 48″ W x 80″ H with 5000 lbs. load capacity, this automatic rotary arm stretch wrapping solution maximizes throughput and efficiency. This system takes care of everything, you only change the roll of film. It can wrap almost anything and is ideal for wrapping very light, very tall or unstable loads. Also great in wash-down and dusty environments. All Wulftec systems come standard with Allen Bradley controls, 20″ No-Thread lifetime warranty on pre-stretch rollers, and much more. Systems are customizable with a full complement of options to your needs and can include safety packages for your environment.

Download PDF

With a production rate of 55 loads per hour, and a 65″ diameter turntable with 5000 lbs. load capacity, this automatic standard base, low-profile turntable stretch wrapping solution will meet a variety of application requirements. All Wulftec systems come standard with Allen Bradley controls, 20″ No-Thread lifetime warranty on pre-stretch rollers, and much more. Systems are customizable with a full complement of options to your needs and can include safety packages for your environment.

Download PDF

With a production rate of 55 loads per hour, and a 51″ x 51″ octagonal turntable with 5000 lbs. load capacity, this automatic standard base, high-profile turntable stretch wrapping solution will meet a variety of application requirements. All Wulftec systems come standard with Allen Bradley controls, 20″ No-Thread lifetime warranty on pre-stretch rollers, and much more. Systems are customizable with a full complement of options to your needs and can include safety packages for your environment.

Download PDF

With a production rate of 50 loads per hour, and a maximum load size of 56″ L x 56″ W x 80″ L with unlimited load capacity, this semi-automatic rotary tower stretch wrapping solution will meet a variety of application requirements. All Wulftec systems come standard with Allen Bradley controls, 20″ No-Thread lifetime warranty on pre-stretch rollers, and much more. Systems are customizable with a full complement of options to your needs and can include safety packages for your environment.

Download PDF

With a production rate of 55 loads per hour, and a 51″ x 51″ octagonal turntable with 5000 lbs. load capacity, this semi-automatic standard base, high-profile turntable stretch wrapping solution will meet a variety of application requirements. All Wulftec systems come standard with Allen Bradley controls, 20″ No-Thread lifetime warranty on pre-stretch rollers, and much more. Systems are customizable with a full complement of options to your needs and can include safety packages for your environment.

Download PDFTalk with an expert.